- Announcement : Sino Folding Carton 2016 will be hel… More >

Location : Home> Flute Lamination Machines

Flute Lamination Machines

Flute Lamination Machines

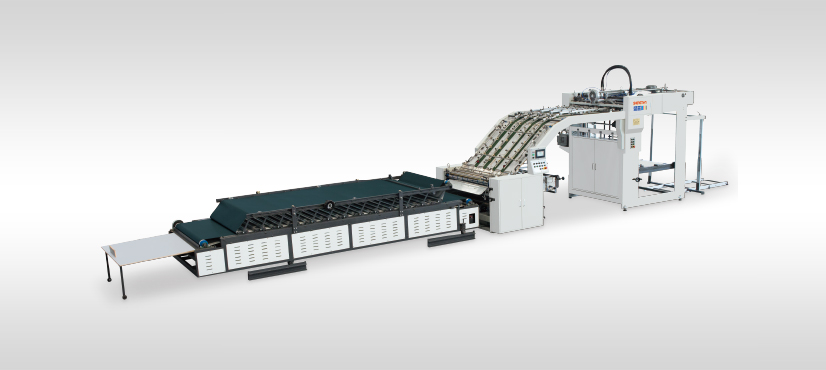

STM Automatic Flute Laminator

Performance of the machine

●STM Series Automatic Flute Laminator adopts unique pressing spring front lay registration design compliant with PLC control system which makes machine run at high lamination precession and low rate of breaking down.

●The machine uses speed variators, PLC central control, simulation to digit program system..

●The core designed rubber roller together with knurled steel roller enhances the evenness of gluing, strength of stickiness, as well as lowering the production cost.

●Balance-tested rollers, tight assembling technique, plus timing belts driving mechanic system makes the machine runs at low noise with high precision.

●The machine adopts automatic glue supply and recyclable glue circulating system.

●Self-developed high-strength feeder compliant with high configuration electric system makes the machine run at low malfunction. The electric parts used are all world wide available brand or well-known Chinese brand.

●All material bought from outside are inspected according to ISO-9001 standard and the key parts such as bearings are imported ones.

●The bottom sheet for this machine can be A, B, C, E, F flute, 3 or 5 ply corrugated board to sheet lamination. The range for top paper can be 150-450 GSM. It has top paper advance or alignment function.

●The machine uses speed variators, PLC central control, simulation to digit program system..

●The core designed rubber roller together with knurled steel roller enhances the evenness of gluing, strength of stickiness, as well as lowering the production cost.

●Balance-tested rollers, tight assembling technique, plus timing belts driving mechanic system makes the machine runs at low noise with high precision.

●The machine adopts automatic glue supply and recyclable glue circulating system.

●Self-developed high-strength feeder compliant with high configuration electric system makes the machine run at low malfunction. The electric parts used are all world wide available brand or well-known Chinese brand.

●All material bought from outside are inspected according to ISO-9001 standard and the key parts such as bearings are imported ones.

●The bottom sheet for this machine can be A, B, C, E, F flute, 3 or 5 ply corrugated board to sheet lamination. The range for top paper can be 150-450 GSM. It has top paper advance or alignment function.

Specifications

| Model | STM-1300 |

| Max. sheet size | 1300×1300mm |

| Min. sheet size | 400×400mm |

| Max. machine speed | 153m/min |

| Total power | 16.25kw |

| Overall dimension | 14000×2300×2700mm |

| Model | STM-1450 |

| Max. sheet size | 1450×1300mm |

| Min. sheet size | 400×400mm |

| Max. machine speed | 153m/min |

| Total power | 16.25kw |

| Overall dimension | 14300×2450×2700mm |

| Model | STM-1650 |

| Max. sheet size | 1650×1600mm |

| Min. sheet size | 400×400mm |

| Max. machine speed | 153m/min |

| Total power | 18.1kw |

| Overall dimension | 14800×2550×2700mm |

Video